In my last

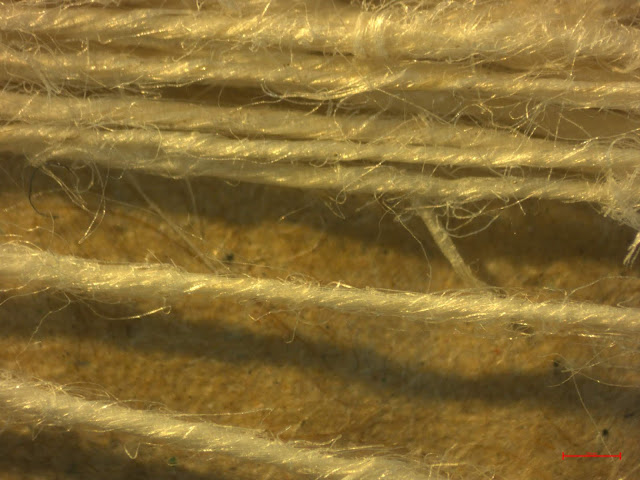

update, I talked about the wool that would have been available to Iron Age people in Europe. I also mentioned that textiles are very rare, and because of the rarity of archaeological samples, we don't really know for sure what type of sheep they used, only that the wool has undergone dramatic changes over time. Some information about wool has been discovered through the scientific testing of sheep skins found contemporaneously, such as the micron count of each part of the sheep (ie, prime fleece, leg wool, etc.).

I've mentioned the "Iron Age" several times now, but I haven't said what I'm calling the "Iron Age." Generally speaking, tool technology advances into subsequently sophisticated tools to make life easier and warfare more deadly. But tool technology doesn't begin everywhere in the world at the same time, and in some cases, two or more tool technologies will be used simultaneously in various parts of the world. And even one a group of people began using a new tool technology, they didn't completely give up on their previous tool technology (can you imagine how ludicrous it would have been for everyone to switch over to cellular phones in 1993 and get rid of house phones?). While most of us know a few details about the Iron Age in general (ahem, they used iron tools), it's important to know from

which Iron Age I'm gleaning information.

The Iron Age I will be referring to throughout my research is in Central Europe (Germany, France, Spain, etc.), Western Europe (Britain, Scotland, and Ireland, etc.), and Northern Europe (Scandinavia). In this part of the world, the Iron Age arrived about a thousand or so years later than it began in the Near East (Egypt, Mesopotamia, and India). If we travel from east to west, the Iron Age began in Central Europe around 850BCE, in Western Europe around 800BCE, and in Northern Europe around 400 (or 300) BCE. The end dates for each aren't quite so clear cut. The indigenous populations in Central, Western, and Northern Europe did not write historical accounts, so much of what we know about them comes from outside contemporaries. The Roman invasion introduced the indigenous people to a historical tradition (and Christianity) and were they were flooded with Roman culture. Rome conquered many cultural traditions in this area of the world, but some, like the Picts in Scotland (around 100BCE), retained their autonomy from the Empire. Generally speaking, the Iron Age 'ended' in Central and Western Europe by the middle of the 5th century, approximately at the time of the fall of the Roman Empire. In Northern Europe, the Iron Age didn't 'end' until as late as the Norman Conquest of England (1066CE).

The Iron Age followed the Bronze Age, and was a critical period of cultural development across the board. Iron tools proved to be more durable and could hold a sharp edge for longer, but most significantly, iron can be forged. The technology used for making bronze items is through a casting method, where the hot metal is poured into a mold and allowed to cool. It could be honed to a sharp edge. Bronze is a softer metal than iron, so it couldn't maintain it's edge for nearly as long. If a bronze weapon chipped or broke, it must be melted and recast again. The differences in smithing techniques for bronze and iron were that iron required a very hot furnace and a specialized annealing process. During this transition period, iron was more used for decorative items than for weapons.

Since the information archaeologists have managed to piece together for any one particular area, temporally and spatially, is rather meager, it behooves me to utilize information from a generalized Iron Age period of 'western' Europe. Textile fabrics do not preserve well, and are most commonly found in environments like bogs, ice, salt (like table salt) mines, and metallic salts (salts produced as metals decay in acidic soil). Because of these specific environments, preserved textiles are contextual outliers--meaning, they are one of a kind given the time period in which they date, and anomalies given that there may only be a few textiles found in a certain geographic region. Inferences must be made about the type/appearance/etc. of textiles in surrounding areas, and the evolution of textile types/appearances/etc. in a single area.

For example, let's say part of a tunic is found in modern-day Paris, France, which dates to 125 +/-25 BCE, and is dyed with woad. We can infer that these people had an advanced understanding of natural dyeing and we can know this by studying modern societies who still use natural dyeing techniques. We can also infer that people in the same area probably knew how to dye with woad as well, especially if the plant is present in that area. For the most part, this assessment would be accepted as a highly probable statement--but that doesn't mean all groups that existed in the same area knew how to dye with woad. Unfortunately, though people buried their dead, they didn't also bury time capsules...we have to go with what we find in the ground.

I'll be using the information about a generalized 'Iron Age' to guide me on my quest to make a warp-weighted loom and use it to weave a scarf (let's shoot for realism). By pulling information from various parts of the western Iron Age world, I'll give myself a better chance of understanding the types of cloth which were made and deciding whether people were making cloth for specific purposes or for mass production. I'll go into those details in my next update, where I will talk specifically about what I've learned regarding loom weights and how to set up a warp to produce the best piece of fabric.

In these updates, I've been trying to merge two different fields of study together, that of archaeology and textile studies, and I hope I am doing them justice. If you feel like I missed something or that I got something wrong, please let me know! I am a master in neither field, but through these personal efforts, I hope to gain some level of mastery of both. In addition to grad school (which should be starting for me this summer), I'll be continuing on with this project until it's completed, no matter how long that takes. With ya'll there to read and offer support, I think I can make it through this daunting task. Thank you for reading about my journey!

I've also updated my bibliography, in case you are keeping up with me:

Current Bibliography:

Albarella, U., Johnstone, C., & Vickers, K. (2008). The development of animal husbandry from the Late Iron Age to the end of the Roman period: a case study from South-East Britain. Journal of Archaeological Science, 35(7), 1828-1848.

Andresen, S. T., & Karg, S. (2011). Retting pits for textile fibre plants at Danish prehistoric sites dated between 800 bc and ad 1050. Vegetation history and archaeobotany, 20(6), 517-526.

Degano, I., Ribechini, E., Modugno, F., & Colombini, M. P. (2009). Analytical methods for the characterization of organic dyes in artworks and in historical textiles. Applied Spectroscopy Reviews, 44(5), 363-410.

Frei, K. M., Berghe, I. V., Frei, R., Mannering, U., & Lyngstrøm, H. (2010). Removal of natural organic dyes from wool–implications for ancient textile provenance studies. Journal of archaeological science, 37(9), 2136-2145.

Good, I. (2001). Archaeological textiles: a review of current research. Annual Review of Anthropology, 209-226.

Joosten, I., van Bommel, M. R., Hofmann-de Keijzer, R., & Reschreiter, H. (2006). Micro analysis on Hallstatt textiles: colour and condition. Microchimica Acta, 155(1-2), 169-174.

Rast-Eicher, A., & Bender Jørgensen, L. (2012). Sheep wool in Bronze Age and Iron Age Europe. Journal of Archaeological Science.

Ryder, M. L. (1987). The evolution of the fleece. Scientific American, 256(1), 112-119.

Strand, E. A., Frei, K. M., Gleba, M., Mannering, U., Nosch, M. L., & Skals, I. (2010). Old Textiles—New Possibilities. European journal of archaeology, 13(2), 149-173.

Tomlinson, P. (1985). Use of vegetative remains in the identification of dyeplants from waterlogged 9th–10th century AD deposits at York. Journal of archaeological science, 12(4), 269-283.

Vanden Berghe, I., Gleba, M., & Mannering, U. (2009). Towards the identification of dyestuffs in Early Iron Age Scandinavian peat bog textiles. Journal of Archaeological Science, 36(9), 1910-1921.

Viklund, K. (2011). Flax in Sweden: the archaeobotanical, archaeological and historical evidence. Vegetation history and archaeobotany, 20(6), 509-515.